Thermoforming

Expert, Efficient Thermoforming Solutions

50 Years in the Making

Experience. Process. People.

For over 50 years, Lane Company has used this winning formula to deliver outstanding plastics solutions through thermoforming to some of the largest retailers and OEMs in the country. We are dedicated to leveraging advanced materials and state-of-the-art technologies to achieve top-quality results for our customers.

Our Thermoforming Methods

Vacuum Forming

With decades of experience forming a variety of materials up to .5” thick in sizes up to 60” x 104” x 36” deep, the Lane Company team is unparalleled in our ability to thermoform your unique project quickly, correctly, and with exemplary quality. Our top-of-the-line equipment coupled with our extensive expertise in vacuum and pressure forming allows us to be flexible, collaborative and a true partner to our clients throughout the entire thermoforming process.

Drape Forming

One of the oldest methods of part creation, drape forming is a process in which a plastic sheet is heated to pliability so it can be pressed, bent, or formed into or over a mandrel or form. Drape forming is favored by those seeking a budget-friendly manufacturing process thanks to its low-cost tooling and fixtures.

Line Bending

Line bending is used to bend plastic into a straight line. The process heats a thermoplastic sheet over a strip heater until it becomes soft, then bends it into any desired angle. Lane Company’s state-of-the-art thermoforming equipment can create multiple bends in one cycle, offering more economical and efficient manufacturing.

Our Thermoforming Process

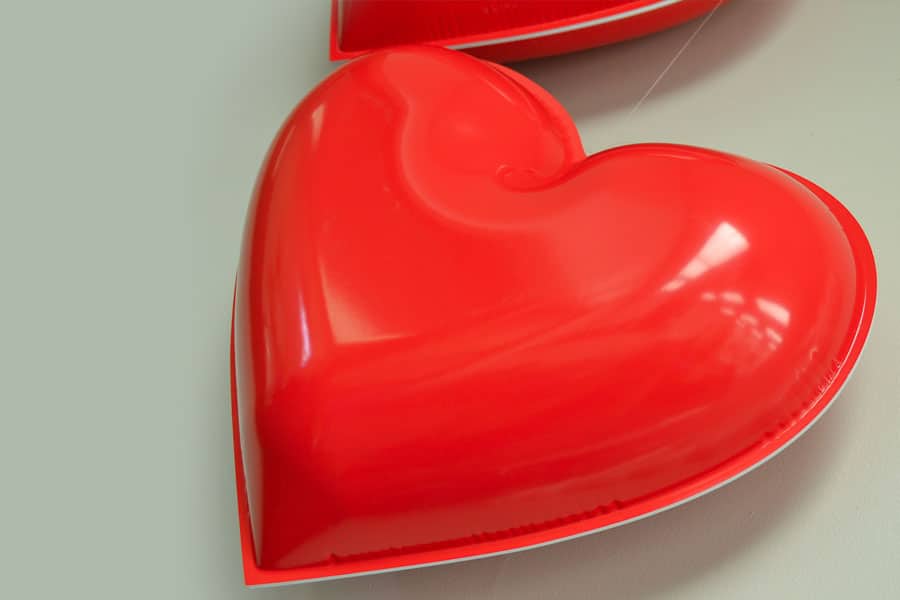

Thermoforming is a manufacturing process in which a sheet of plastic material is heated to pliability and formed to a three-dimensional shape through vacuum and pressure, followed by trimming and finishing to create a usable product or part. Here’s how it works:

Step 1 | Concept

As with any project that requires a manufacturing process, a strong concept is the first step. Thermoformed products run the gamut, ranging from aesthetic to functional pieces, and each concept presents its own unique features and challenges. Our clients often present us with an initial model, or CAD file that we fine-tune into a model, that we then use to determine which plastics processes will best match the project’s needs and goals.

Step 2 | Material Selection

Once the concept is completed, the next step is to determine which plastic material best suits the project. Each type of plastic has something unique to offer in its characteristics and qualities. Our expert engineers will evaluate the project’s needs and make recommendations for the most appropriate materials.

Step 3 | Tooling

Next, a mold must be created for the chosen materials to form to during the manufacturing process. Molds are typically made of aluminum, as it works best for physical processing. It’s at this stage that our engineers will look for areas of potential time and cost savings on behalf of our clients, as there are many different ways to reach the same outcome: A high-quality, functional mold.

Step 4 | Thermoforming

With the mold created, it’s now time for the thermoforming process to take place. The plastic material of choice is heated to the aluminum mold and formed using air pressure and/ or vacuum pressure. It is then cooled and removed from the mold to set.

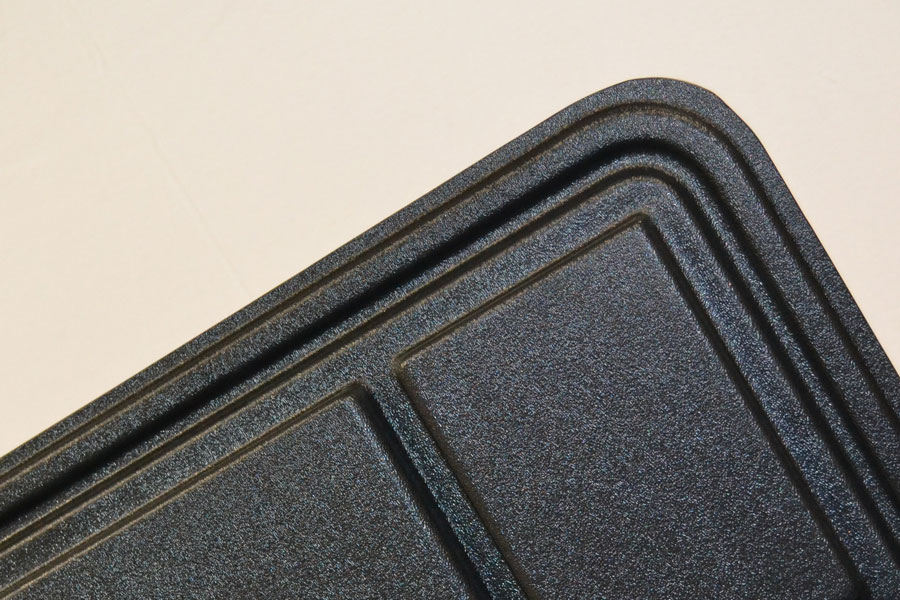

Step 5 | Trimming

Once a piece of plastic is thermoformed, there’s still some material that needs to be trimmed away. At Lane Company, we use 3- and 5-axis CNC routers to quickly cut complex and precise shapes, resulting in faster production times and more accurate, flexible cuts. We also perform secondary operations such as cutouts, through holes, and other features that require the removal of material at this stage in the process.

Step 6 | Secondary Operations

After the custom plastic piece has been created, Lane can also perform a variety of secondary operations and value-add services. These can include the installation of inserts and other fastening devices, and the assembly of hinges, handles, and other hardware if necessary. When a client receives their completed part from Lane Company, that part is ready to seamlessly integrate with the rest of their manufacturing process.

Thermoforming Tolerance Guide

| Activity | Tolerance | Guideline |

| Formed Measurements | +/- .020”- .030” depending on material selection | Additional .001 Per Inch Beyond 12” |

| Drilled Hole Diameters | +/- .005” | Holes Equal or Lesser than 1” |

| Drilled Hole Diameters | +/- .010” | Holes Greater Than 1” to 5” |

| Slots | +/- .010” | Slots Equal or Lesser Than 1” in Any Direction |

| Slots | +/- .020” | Slots Greater Than 1” |

| CNC Trimming | +/- .020” | Includes Hole Diameters Greater than 5” |

| CNC Trimming | +/- .020” | Trim Feature to Trim Feature Distance is Greater than 5” |

Let’s work together.

Combined with our proven supply chain management, these services allow us to function as a convenient single-source partner for many of our customers. Contact us to learn more about how we can help you bring your project to life.